Ruymor also has a tools and maintenance section that supports and complements the production lines. It includes all the machinery needed to respond immediately to any urgent requirements (wire EDM equipment, mills, rectifiers, etc.)

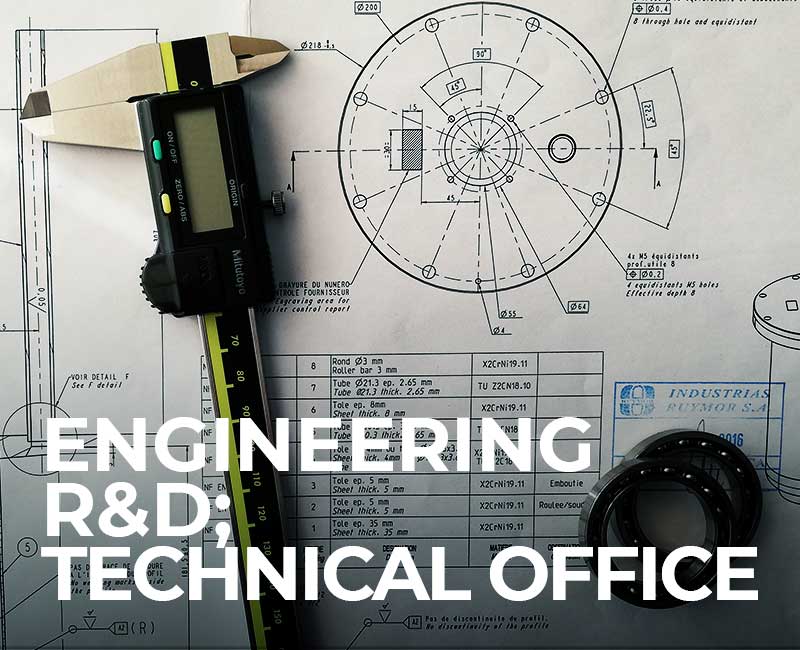

We offer our customers an end-to-end service covering all the phases of production, from creating drawings (CAD-CAM) to delivery of the finished product to any destination.

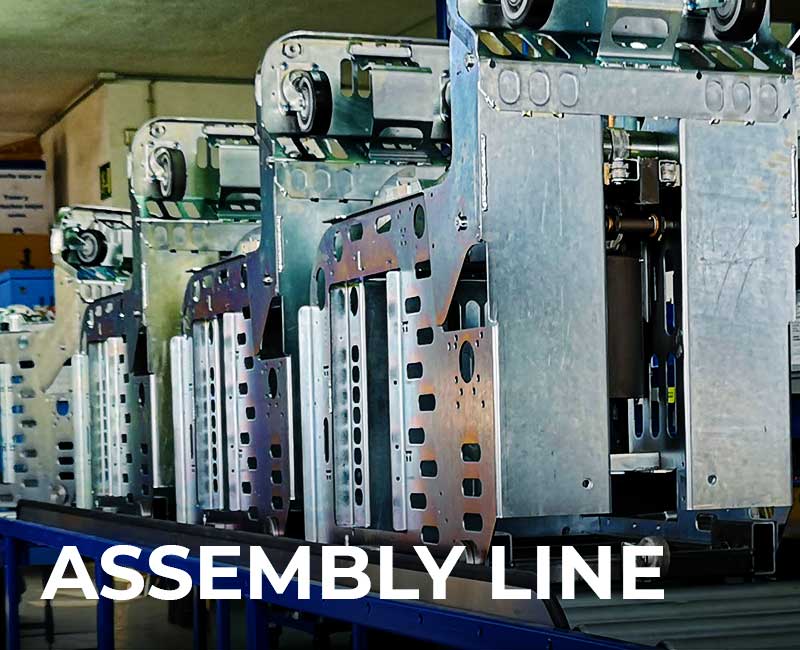

Ruymor has the most versatile and complete human and material resources available for all its sheet metal working processes, machining centres and equipment assembly. They all meet the most stringent quality standards.

Ruymor also has a tools and maintenance section that supports and complements the production lines. It includes all the machinery needed to respond immediately to any urgent requirements (wire EDM equipment, mills, rectifiers, etc.)

Ruymor has its own technical and engineering office, which creates designs and draws up technical and construction viability studies on request from our customers.

Automated feed stamping presses of up to 250 tons and hydraulic presses of up to 400 tons.

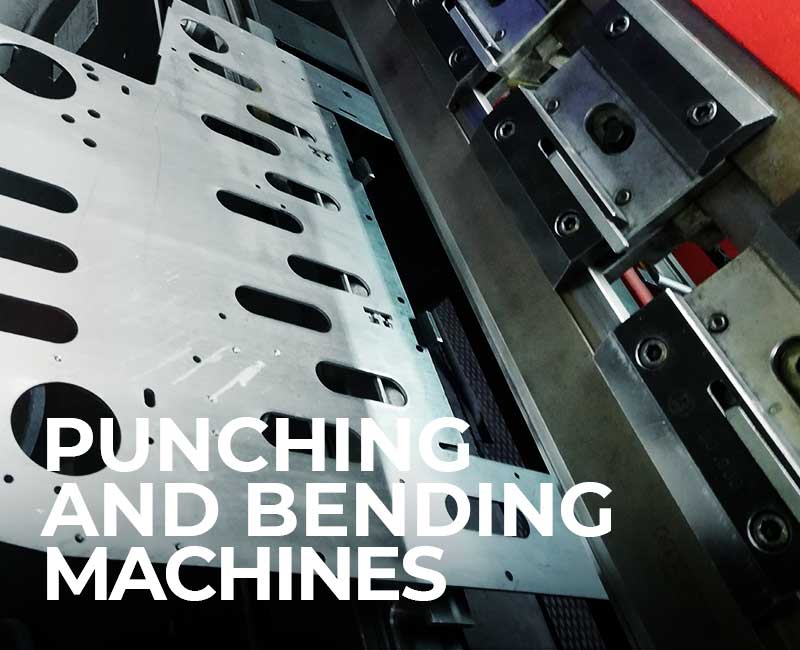

Punching presses and bending machines of up to 180 tons that allow us to punch a thickness of up to 6 mm and bend a length of up to 4 m.

Machining centres, CNC lathes, CNC milling machines, a tangential rectifier, etc.

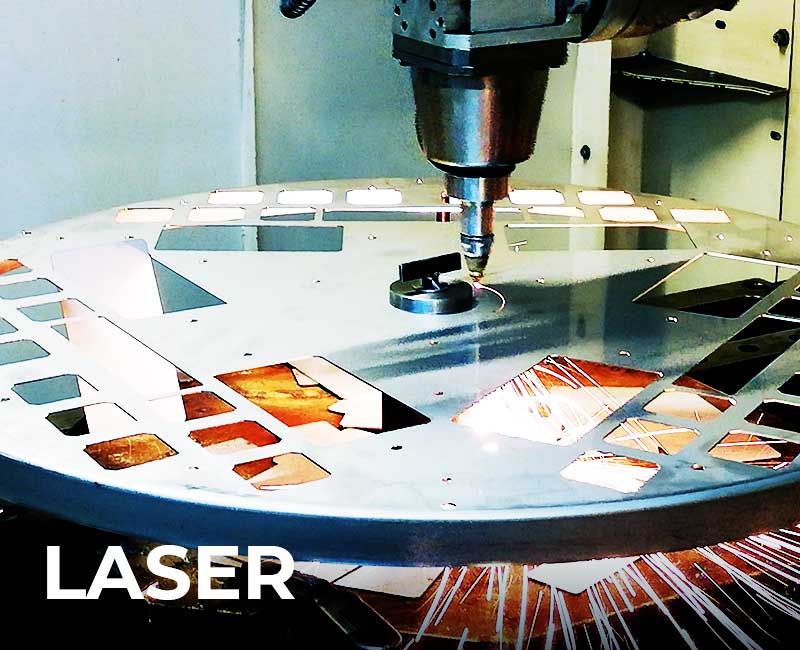

We have four of these centres, making us a sector leader in precision 3D cutting.

Our welding is certified by the ISO 3834-2 standard and we number an International Welding Technologist (IWT) among our staff.

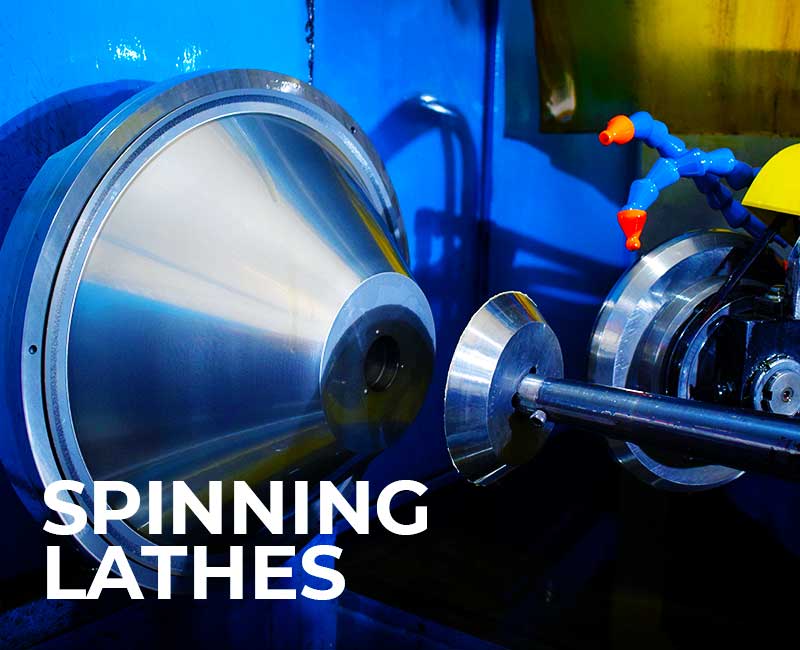

With five CNC spinning lathes, Ruymor provides world-class manufacture of precision conical metallic pieces.

We assemble and mount mechanical and electro-mechanical kits in accordance with the Lean Manufacturing management model.

As specialists in the manufacture of welded stainless steel pieces and kits, we have specific sanding, grinding and polishing areas that achieve levels of roughness of as little as 0.05 microns.